For free cutting materials I use the drill sizes you listed. The tapping drill size I use depends on the material, for tough materials like stainless steel I use larger dill sizes than the ones you listed. I use the sizes given in the Zeus book,unless I find it a bit tight,then I go a little bit bigger,since taps are not a throw-away item,not with me,anyway. This thread is long past its use by date!Īpart from M2.5 which I use a 2.1mm drill for I drill as you have listed 95% of the time, may go a bit larger if it is just a quick thread to hold something that does not rally take any load. I remember the common sizes I use and look up the rest on the internet when I need them. If you can’t buy the book and have a ‘puter to browse on here, they are all listed on numerous websites. Having now got the Tubal Cain book mentioned above I’m now going to try going up. I always use the recommended sizes that most charts list so for metric coarse threads these are, from M2.5 to M8: I know this is an old thread but it saves starting a new one and the links above are still useful. Harold Hall has some similar Tap drill pages on his website that I find useful. Thanks for the LMS Tap drill chart Will, comes in handy for those who don't have access to Tubal Cains book. He gives tables of tapping sizes for each thread size for a range of thread engagements.Īctually, if you have - or get - this book, it's worth reading from cover to cover.

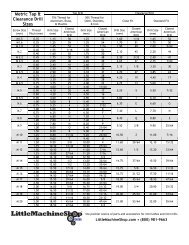

LITTLE MACHINE SHOP DRILL TAP CHART SERIES

Yes, it was Tubal Cain in the Workshop Practice Series No 12 "Drills Taps and Dies". This reminded me of the instructions of one of the past greats (can't remember which one - Tubal Cain perhaps), who suggested that Model Engineers should be using slightly larger diameter holes to aid tapping. But after looking at this link, I will try as they suggest and see how it works for me. I have occasionally drilled oversize, but do not normally have any big issues tapping steel, although I have always winged it with Stainless and guessed a slightly bigger diameter to save damaging the tap. It may have cropped up before on this forum, but I cannot remember reading it. It also said that this principle is used for the data in Machinery's Handbook. The discussion string also stated that larger diameters should also be used for deep holes. The interesting thing for me is that they specify "oversize" tapping holes of 50% for steel / stainless etc. Found a reference to this handy chart on another forum (Practical Machinist) that I thought may be of interest.

0 kommentar(er)

0 kommentar(er)